Variations on the Oriented Layer Prototype series consist of the same basic elements: layers of Phragmites australis reed bundles oriented in parallel (side-by-side), and adjoining floatation elements. The prototypes vary in the number and arrangement of their layers, as well as the size and arrangement of the foam floatation. They all provide a flat platform for the living marsh grass, and allow for a range of buoyancy approaches under the rigid oriented layers of reeds.

How It’s Made

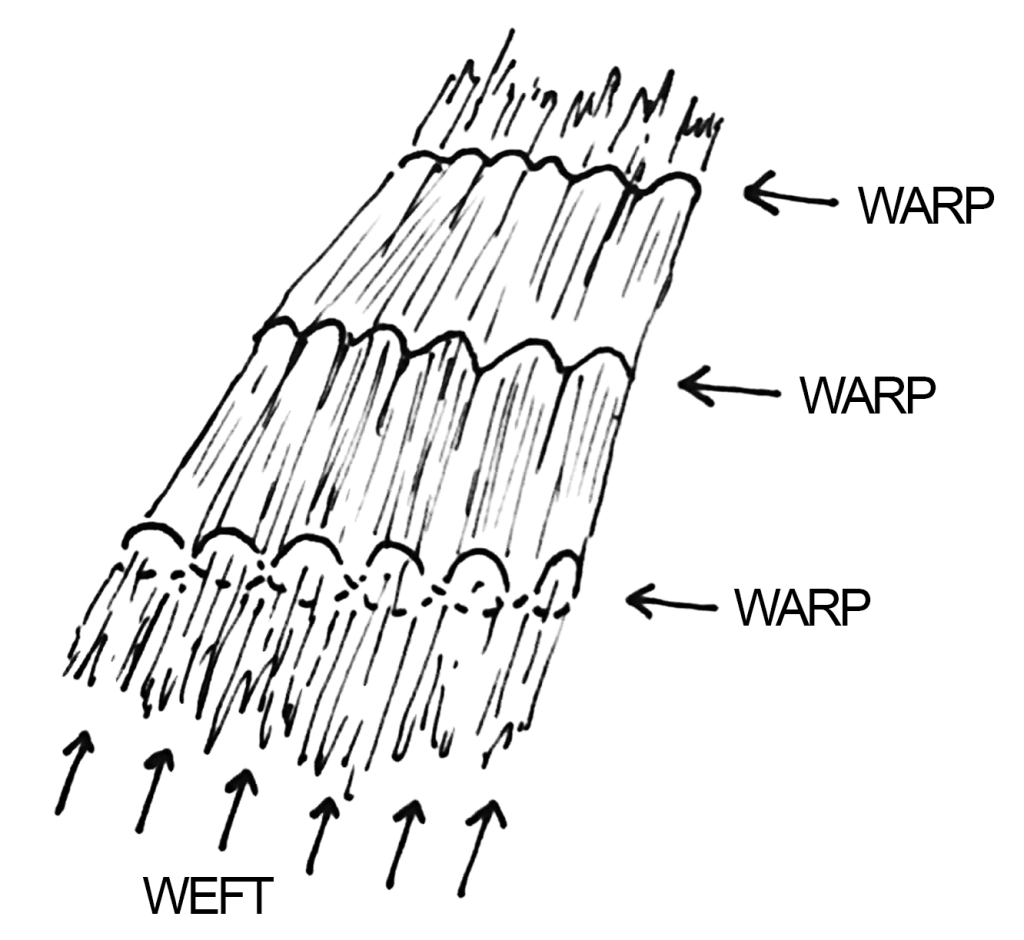

For each layer, small bundles of dead Phragmites reeds are laid side-to-side (“weft”) and are woven together with thin nylon string (“warp”). The resulting mat is flexible in the warp direction, and rigid in the weft direction, similar to “matchstick” rolling window blinds or a sushi mat. This method is straightforward and quick to assemble, requiring no special tools.

These layers are then stacked at different rotation angles. We tried two layers at 90° and three layers at 120°. After stacking, the layers are laced together using an oversized fiberglass needle and thin nylon string. Sewing upward and downward through multiple layers tightens them together, thus creating the base substrate of the Oriented Layer prototype family, a rigid and tight platform.

Since the bundles of reeds are straight rather than wrapped into curves, their ends are exposed. Therefore, each of the oriented mat layers tend to be ragged at two sides—the edges are trimmed for evenness, but these sides and especially the corners are weak points. One version added a thick bundle of reeds wrapping 360° around the exposed edges of the oriented layers to cover the fragile reed ends.

Rectangular bars of polystyrene foam were affixed to the bottom of the prototype, with the same manual lacing method. We tried several arrangements of foam elements, integrating the tension yoke attachment between layers or alongside lashed bundles containing polystyrene foam bars.

Deployment Locations

The Piers Park waterfront site floating frame held three prototypes of the Oriented Layer style. The prototypes were attached directly to the frame by the tension yoke rope in three directions. The frame structure allowed for these prototypes to remain upright and stable, while keeping external tensions consistent throughout the rise and fall of tides.

Successes & Failures

Successes:

- This method produces a highly rigid mat which enables more compact buoyancy foam to be used rather than a single large flat sheet—the concentrated buoyancy force is distributed evenly by the rigid surface, and does not result in point load areas of deformation.

- The woven reed bundle layers use only Phragmites reeds and nylon rope, no coconut fiber, making it the cheapest prototype with the lowest carbon footprint.

Failures:

- The ends of the reed bundles point outward and are therefore exposed, so they tend to shift and loosen unless directly lashed to an adjacent layer. This results in some material loss and less stability away from the center. Also, frayed edges are less conducive to plant root stability which exacerbates the risk of further loss over time.

- Since the reed layers are each oriented in a single direction, it is more difficult to firmly affix the frictional tension yoke to the substrate material. The yoke was more likely to shift along the direction of the reed layers.