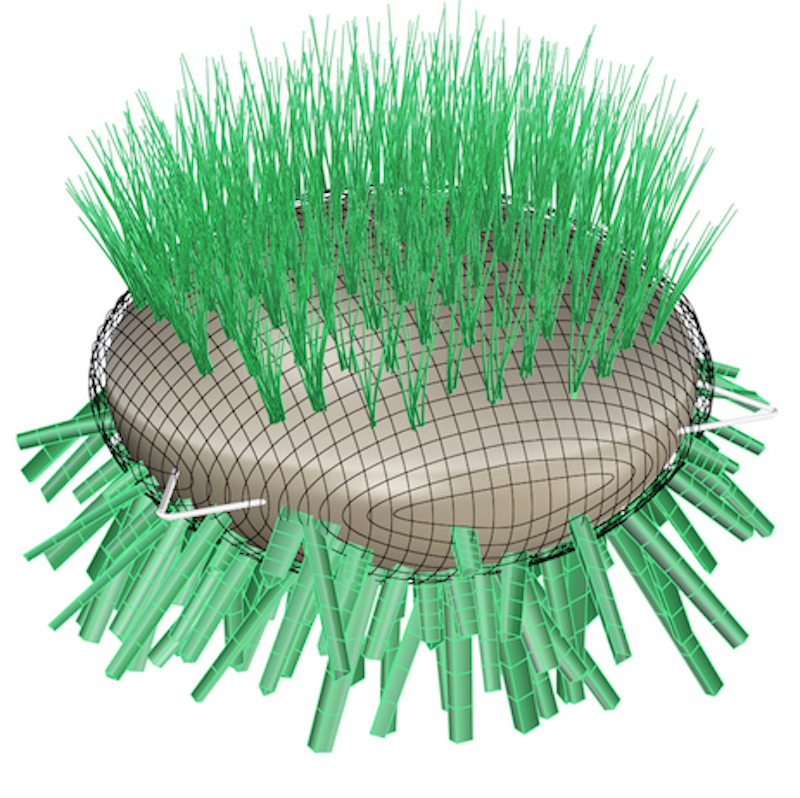

Encasement: Outer Net Pouch

The net holds the unit together and ensures the inner components stay tightly packed inside. Additionally, it provides a strong surface for the growth of seaweeds, macroalgae, and other larger aquatic organisms. The natural coconut fibers are strong, durable and inert in marine conditions.

Salt Marsh Vegetation

Spartina alterniflora (smooth cordgrass, or marsh grass) is the main emergent (above-water) growing species. Dense root mass extends down into the substrate, further binding the substrate materials together over time.

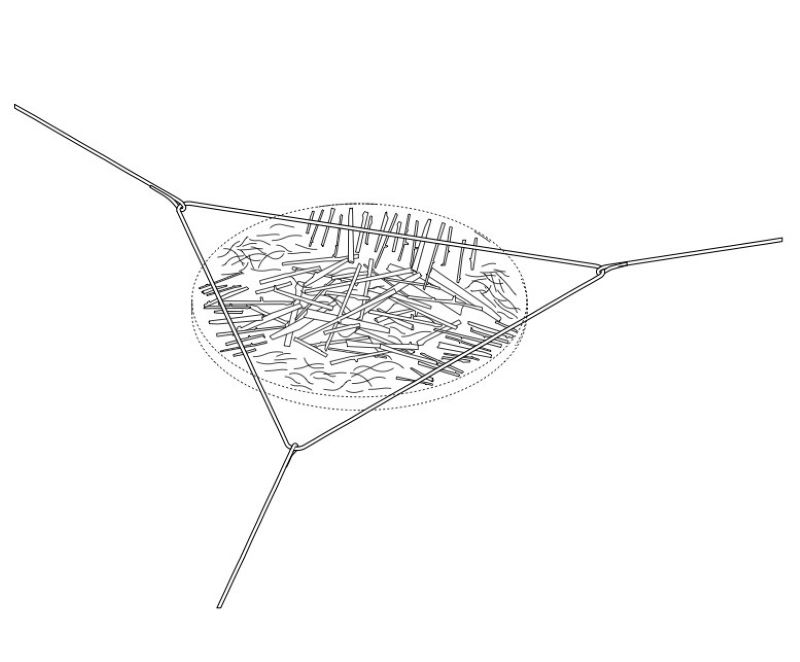

Frictional Tension Yoke

The Y-shaped centrally-connective line extends through the volume of the unit. This element transfers network pull forces to the bulk of the unit rather than stressing the outer net or a singular edge point.

Growing Substrate

Reeds of the invasive Phragmites australis are harvested and used to make up the bulk of the floating mat. The reeds provide buoyancy and a stable structure for the marsh grass to grow and for aquatic vegetation to colonize. We harvest and trim the reeds to ensure the rhizomes and seed heads are excluded from our mat and do not contribute to further spread of this invasive species.

Floatation Elements

A small amount of marine-grade foam provides sufficient buoyancy to maintain floatation for the individual units. The growing substrate (Phragmites reeds) are naturally buoyant, but will lose their ability to provide buoyancy as they get waterlogged and degrade.